热门关键词:济南彩钢板 | 济南复合板 | 济南彩钢瓦 | 济南c型钢 | 济南钢结构 |

新闻中心

联系我们

耀世娱乐

联系人:孙经理

电话:18963458998

地址:耀世娱乐济南市工业北路81号北邻

C型钢的厚壁质量是怎么控制的呢?

来源:http://sxhtyz.com/ 日期:2020-11-17 发布人:

C型钢的厚壁质量是怎么控制的呢?不同的用户对C型钢的厚度有不同的要求。假如要同时知足这些要求,所选的C型钢出产工艺和设备非常枢纽。一般来说,冷轧很难出产出高质量的C型钢,所以要用C型钢机来完成。

How to control the thick wall quality of C-section steel? Different users have different requirements for the thickness of C-section steel. If we want to meet these requirements at the same time, the selected C-beam production process and equipment is very pivotal. Generally speaking, cold rolling is difficult to produce high-quality C-beam, so it needs to be completed by C-beam mill.

物料从C型钢机尾部进入后,被各种压辊压下,成型后的C型钢从机头输出。这不仅大大优化了必要的出产加工工艺,而且进步了产量。它还能保证C型钢产品具有平均的壁厚和复杂的界面外形。

After the material enters from the tail of the C-beam machine, it is pressed down by various rollers, and the formed C-beam is exported from the machine head. This not only greatly optimizes the necessary production and processing technology, but also improves the output. It can also ensure the average wall thickness and complex interface shape of C-beam products.

为了达到正确的壁厚,在压制C型钢时,C型钢机使用的模具由正确的上模具和一些具有相同尺寸、规格和尺寸的下模具组成。为了在加工前将它们安装到位,不仅需要确保上模和下模的平稳运行,还需要确保附近的间隙平均,以便压制的C形钢可以具有平均的壁厚。

In order to achieve the correct wall thickness, the die used by the C-beam machine consists of the correct upper die and some lower dies with the same size, specification and size. In order to install them in place before processing, it is necessary not only to ensure the smooth operation of the upper and lower dies, but also to ensure that the adjacent gaps are even so that the pressed C-shaped steel can have an average wall thickness.

在加工C型钢的过程中,安装模具并对主机进行测试。然后启动空气压缩机、真空泵、挤出机、切砖机、给料机、压砖机、主机和瓷砖输送机。泊车时,休止挤压机,然后休止其余设备。

In the process of processing C-section steel, the mould is installed and the main engine is tested. Then start the air compressor, vacuum pump, extruder, brick cutter, feeder, brick press, host and tile conveyor. When parking, first stop the extruder and then rest of the equipment.

我们在使用设备前,检查连接是否牢固,安装螺栓螺母是否拧紧,用电启动发念头试运转前,在左右底盘加足够的润滑油。从挤出机挤出的泥坯由切割机切割成固定长度,由辊式输送机输送到压砖机,并由装载机按照指定程序输送到下模。将由C型钢机压制的砖坯在工作台上分度后,由卸砖机的真空吸盘吸附,分度后放置在输送线的砖坯支架上。

Before using the equipment, we should check whether the connection is firm, whether the mounting bolts and nuts are tightened, and add enough lubricating oil to the left and right chassis before starting the engine with electricity. The slurry extruded from the extruder is cut into a fixed length by the cutter, transported to the brick press by the roller conveyor, and transported to the lower die by the loader according to the specified procedure. After dividing the brick blank pressed by C-beam machine on the worktable, it is absorbed by the vacuum suction cup of the brick unloader, and is placed on the brick blank support of the conveying line after graduation.

用该C型钢机制造的C型钢的壁厚可以做得很薄,大大简化了出产工艺,进步了出产效率。它可以出产各种均匀壁厚但截面复杂的型材和不同材质的冷弯彩钢设备,这些都是普通热轧方法难以出产的。

The wall thickness of C-section steel made by this machine can be made very thin, which greatly simplifies the production process and improves the production efficiency. It can produce all kinds of profiles with uniform wall thickness but complex cross-section and cold-formed color steel equipment of different materials, which are difficult to produce by ordinary hot rolling method.

以上是关于C型钢的厚壁质量是怎么控制的相关介绍,希望大家看完能有所帮助,想要了解更多济南c型钢内容欢迎关注我们的网站。

The above is about how to control the thick wall quality of C-section steel. I hope you can help after reading. If you want to know more about Jinan C-section steel, please pay attention to our website.

下一篇:使用济南复合板胶粘之前为何进行处理? 上一篇:济南彩钢板的装拆操作及结构可靠性

此文关键词: 济南C型钢厂

阅读/ Recommended reading

- 济南彩钢板:彩钢板常见质量问题 2024-09-21

- 济南彩钢板:彩钢瓦生锈了怎么办? 翻新需要打磨吗? 2024-09-03

- 济南彩钢瓦厂:树脂瓦与彩钢瓦谁耐用 2024-09-02

- 济南C型钢厂:关于C型钢常见知识与抗震支架应用的相关知识 2024-08-28

济南彩钢板种类及介绍

[2018-08-23]

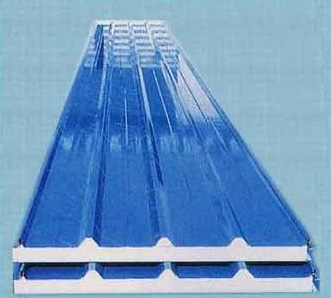

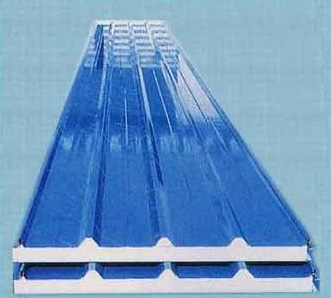

彩钢夹芯板是由上下两层彩色涂层钢板作为面板,以保温隔热材料聚苯乙烯、聚氨脂、酚醛泡沫、岩棉等为芯材,在专用的自动化生产线上,经连续成型工艺将芯材与面板复合成整体的建筑板材,俗称为...